End-to-end solutions from raw materials to production equipments for PU foam and mattress.

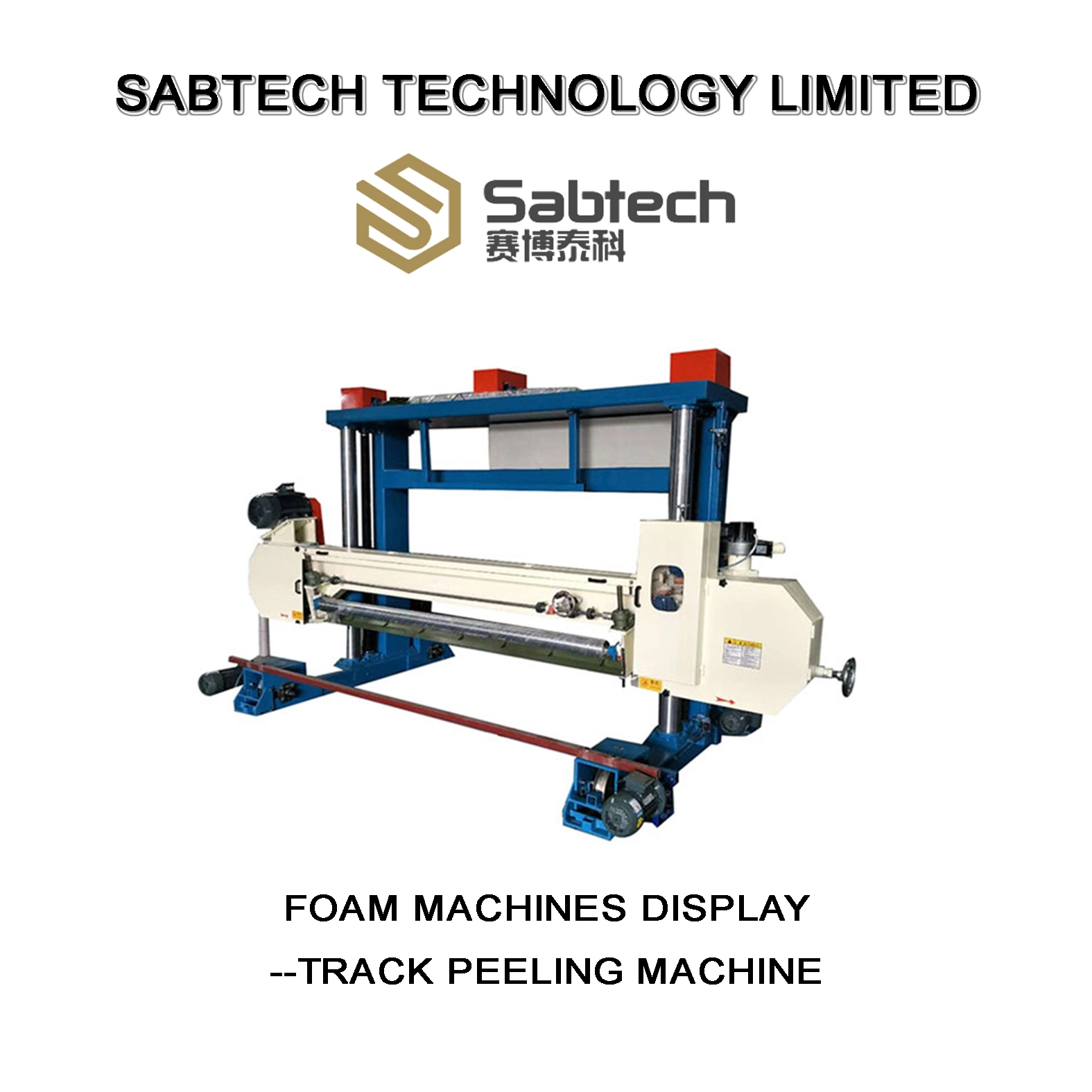

Track peeling machine(SAB-TP)

This track peeling machine primarily serves the purpose of longitudinally slicing continuous foaming sponge. The cutting speed is regulated by an imported frequency converter, ensuring stable operation and high production efficiency. It stands as an indispensable asset for continuous foam production lines.

Additionally, this machine can be furnished with a fixed steel bracket platform, which effectively enhances the friction between the sponge and the platform, leading to a significant improvement in cutting quality and increased sponge utilization.

Product Features

1. Small footprint, easy operation, and high production efficiency.

2. It is an essential auxiliary equipment for continuous foam production manufacturers (this machine can be optionally equipped with an automatic material collection device for even higher efficiency).

3. This machine can be equipped with a steel bracket-fixed platform, effectively increasing the friction between the foam and the platform, significantly improving the quality of cutting, and enhancing foam utilization.

4. Custmized requirements are welcome.

5. OEM design is welcome.

Related Parameters

| Model No | SAB-TPL-1650 | SAB-TP-2150 |

| Cutting Foam Width | W1650mm | W2150mm |

| Cutting Foam Height | H1200mm | H1200mm |

| Cutting Thickness | 2-60mm | 2-60mm |

| Treading Speed | 0-60m/min | 0-60m/min |

| Blade Length | L7400mm | L8400mm |

| Total Power | 8.92KW | 10.42KW |

| Machine Weight | 1500Kgs | 1800Kgs |

| Overall Size(L*W*H) | 3550*2640*2350mm | 4050*2640*2350mm |

Product Detail

top-notch service

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.

Sabtech Technology Limited is rooted in the foundational technical expertise of machinery and backed by over 20 years of experience in mattress and PU foam manufacturing. Our aim is to produce economically efficient, high-performance, user-friendly, and low-maintenance polyurethane foam and mattress machinery.

We have five production factories, access to resources from ten chemical material factories, and collaborations with over 100 furniture manufacturers in our supply chain. Our team includes five engineers specializing in polyurethane engineering, mechanical engineering, and circuit design, offering personalized one-on-one production technology training. An 8-person after-sales service team commits to responding within one hour. There are sample machines in the workshop available for on-site mechanical operation demonstrations at any time.

To date, we have served 18 factories, assisting them in constructing, upgrading, and renovating their facilities. Providing professional insights for over 60 mattress and PU foam factories on factory planning and layout optimization, improving equipment efficiency, and reducing costs. Resolving mechanical operation issues, quality problems in foaming, and raw material waste issues for over 80 factories.

We meticulously craft every detail of our machines, striving to make them serve workers better, reduce complexity, alleviate the burdens on frontline production workers, increase production efficiency, reduce production costs, and minimize maintenance issues.

Production Process

We believe that it is foolish to sell any fixed type of machinery. Machinery should be upgraded according to different production scenarios to maximize efficiency.

Contact Person: Ruby Lau

Contact Number: +86-18688267265

Email: sales@alforu.cn

WhatsApp: +86-18688267265

Company Address: NO. 18 South Industry Road, Dongguan City, Guangdong Province China