End-to-end solutions from raw materials to production equipments for PU foam and mattress.

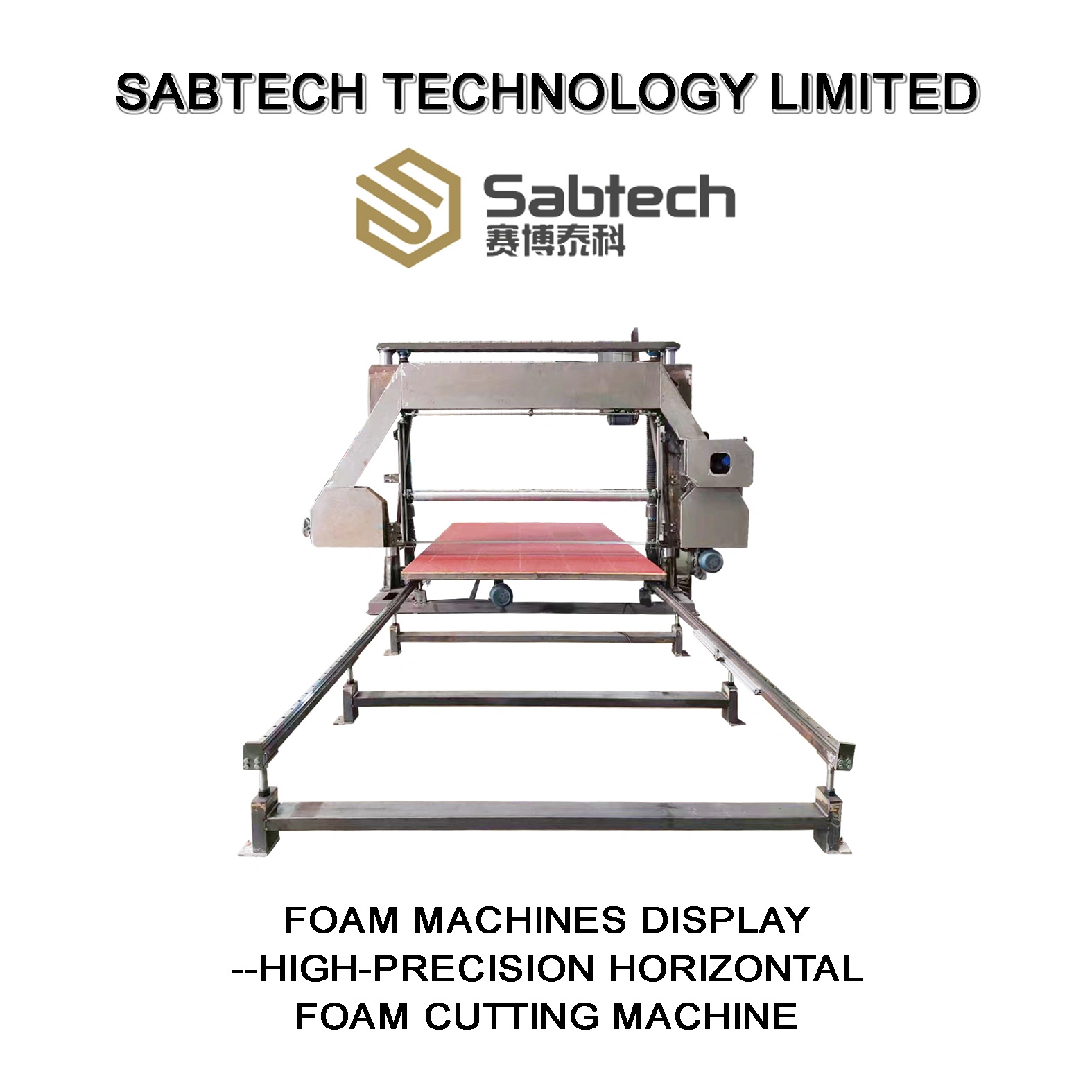

High-Precision Horizontal Foam Cutting Machine(SAB-HC01)

The high-precision horizontal foam cutting machine is a specialized piece of equipment used to slice large polyurethane foam blocks into thin, even sheets. It plays a vital role in the processing of flexible polyurethane foam for industries such as mattresses, furniture, automotive interiors, insulation materials, and packaging.

Core Functions & Features:

Precision Cutting:

Equipped with a high-tension cutting blade or band knife system, it delivers uniform thickness and smooth surfaces.

Adjustable Cutting Settings:

Parameters such as thickness, blade speed, and feeding speed can be flexibly adjusted for different foam types and production needs.

Material Versatility:

Capable of cutting conventional flexible foam, high resilience (HR) foam, memory foam, composite foam, etc.

Safety Features:

Includes emergency stop buttons, blade protection covers, and power-off safeguards for secure operation.

Stable Work Platform:

Built with a reinforced flat table or conveyor to maintain precision and stability during cutting.

Functional Role:

This machine is essential for transforming foam blocks into sheets of precise dimensions, ensuring consistency in size and quality for downstream applications.

Application Value:

Ideal for use in mattress manufacturing, soft furniture production, and technical foam processing, the horizontal foam cutting machine enables efficient preparation of foam layers for lamination, bonding, or profile shaping. It supports high-volume, accurate, and standardized production, making it a core machine in modern foam product workflows.

Product Features

1.Exceptional Precision

This high-precision horizontal foam cutting machine utilizes precision-engineered linear guide rails and a tight-tolerance cutting frame to deliver highly accurate and repeatable cuts, ensuring every sheet is uniform in thickness.

2. Superior Stability & Smoothness

Thanks to its reinforced welded structure and precision-guided motion system, the machine operates with outstanding stability. This minimizes vibrations during cutting, which in turn reduces material shifting and keeps cut edges sharp and even.

3. Quiet, Low-Noise Operation

The use of recirculating ball or roller carriage linear rails significantly reduces friction and dampens noise. This results in a smoother, quieter cutting process—ideal for factory environments and operator comfort.

4. Enhanced Lifespan & Minimal Wear

With reduced friction and high-quality, wear-resistant rails, key components require less maintenance. This translates to longer service life, fewer replacements, and lower total cost of ownership.

5.Consistent High Quality Output

The combined benefits of precise motion, stable structure, and smooth operation guarantee reliable performance. Users can expect uniform foam sheets ideal for critical downstream processes like lamination, bonding, or contour cutting.

Related Parameters

| Model | SAB-HC01 |

| Available cut foam size | W2150*L3000mm |

| Cutting foam height | 1200mm |

| Cutting speed | 0-25m/min |

| Cutting thickness | 2-200mm |

| Blade Length | 9500mm |

| Motor power | 8.24KW |

| Guide rails | Linear guide rails |

Product Detail

top-notch service

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.

Sabtech Technology Limited is rooted in the foundational technical expertise of machinery and backed by over 20 years of experience in mattress and PU foam manufacturing. Our aim is to produce economically efficient, high-performance, user-friendly, and low-maintenance polyurethane foam and mattress machinery.

We have five production factories, access to resources from ten chemical material factories, and collaborations with over 100 furniture manufacturers in our supply chain. Our team includes five engineers specializing in polyurethane engineering, mechanical engineering, and circuit design, offering personalized one-on-one production technology training. An 8-person after-sales service team commits to responding within one hour. There are sample machines in the workshop available for on-site mechanical operation demonstrations at any time.

To date, we have served 18 factories, assisting them in constructing, upgrading, and renovating their facilities. Providing professional insights for over 60 mattress and PU foam factories on factory planning and layout optimization, improving equipment efficiency, and reducing costs. Resolving mechanical operation issues, quality problems in foaming, and raw material waste issues for over 80 factories.

We meticulously craft every detail of our machines, striving to make them serve workers better, reduce complexity, alleviate the burdens on frontline production workers, increase production efficiency, reduce production costs, and minimize maintenance issues.

Production Process

We believe that it is foolish to sell any fixed type of machinery. Machinery should be upgraded according to different production scenarios to maximize efficiency.

Contact Person: Ruby Lau

Contact Number: +86-18688267265

Email: sales@alforu.cn

WhatsApp: +86-18688267265

Company Address: NO. 18 South Industry Road, Dongguan City, Guangdong Province China