End-to-end solutions from raw materials to production equipments for PU foam and mattress.

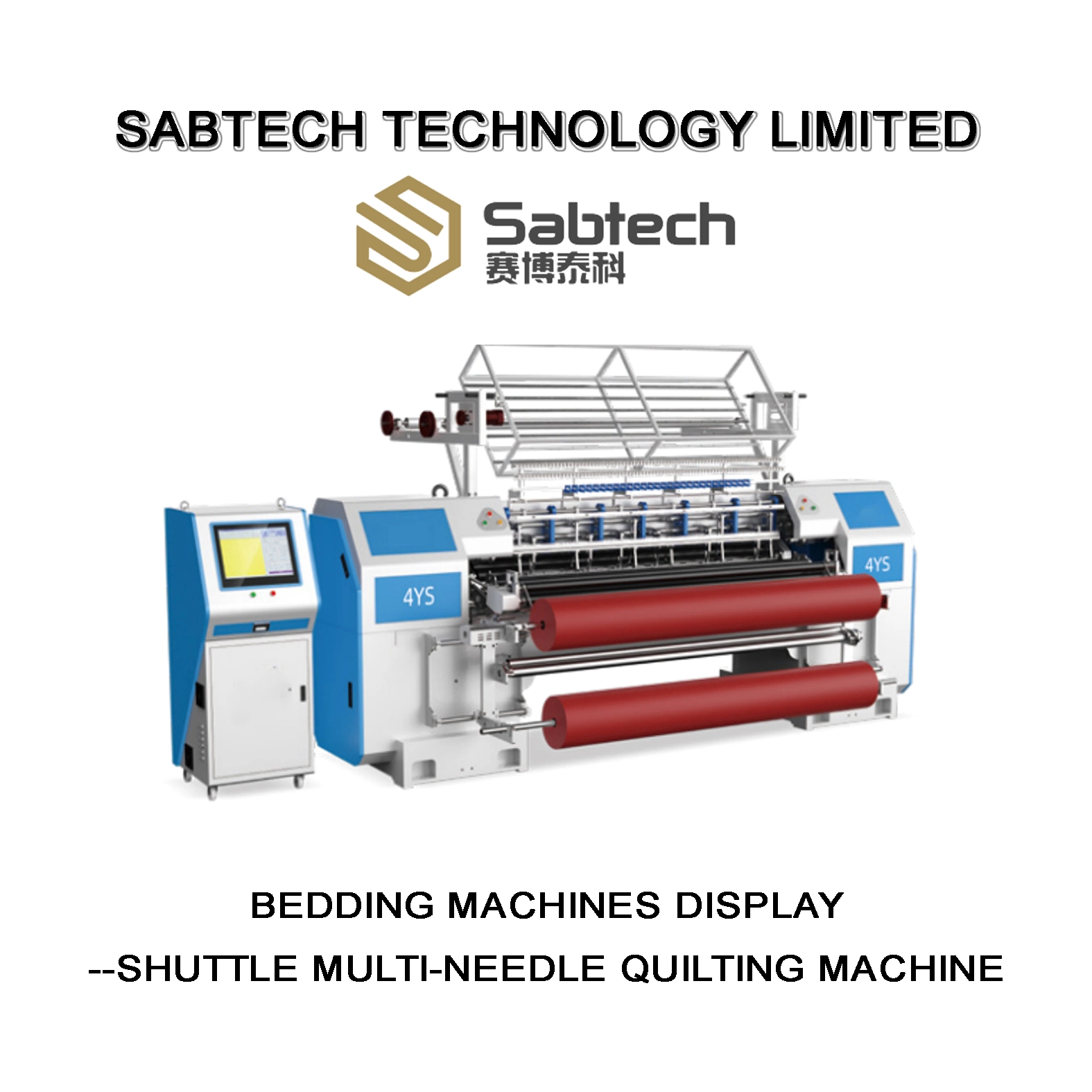

Lock stitch multi needle quilting machine(SAB-MQ02-4YS)

The lock stitch multi needle quilting machine is versatile and suitable for quilting a wide range of products, including clothing, mattress covers, handbags, gloves, sleeping bags, pajamas, quilt covers, bedspreads, seat covers, and various home decor items. It offers the capability to create diverse stitching patterns.

Product Features

1. Innovative shuttle guide rail with U-shaped bearing for durability and stability.

2. Advanced computer control system and mechanical processes for reduced machine noise.

3. Needle bar frame structure without oiling prevents fabric oil contamination and offers durability with low maintenance costs.

4. Frequency-controlled main shaft and servo-driven saddle and roller for automatic needle control.

Related Parameters

| Model | SAB-MQ02-4YS (66") | SAB-MQ02-4YS (96") | SAB-MQ02-4YS (128") |

| Oveall Size | 3600*1250*1780mm | 4700*1370*1780mm | 5590*1370*1780mm |

| Overall Weight | 2800KGS | 3500KGS | 3800KGS |

| Quit width | 1700 | 2450 | 3300 |

| Space between needle rows | 76.2 | 76.2+76.2 | 76.2+76.2 |

| Space between needles | 25.4 | 25.4 | 25.4 |

| X stroke | 203.2 | 304.8 | 304.8 |

| Quilting thickness | ≤ 30mm | ≤ 30mm | ≤ 30mm |

| Stitch | 2-7mm | 2-7mm | 2-7mm |

| Output(per hour) | 60-150m/h | 60-130m/h | 60-130m/h |

| Pin type | 14#-21# | 14#-21# | 14#-21# |

| Spindle speed | 500-1000 (RPM) | 500-1000 (RPM) | 500-900 (RPM) |

| Voltage(AC) | 380V/220V 50Hz/60Hz 3Phase | 380V/220V 50Hz/60Hz 3Phase | 380V/220V 50Hz/60Hz 3Phase |

| Power | 4 kw | 4.5kw | 5.5 kw |

Product Detail

top-notch service

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.

Sabtech Technology Limited is rooted in the foundational technical expertise of machinery and backed by over 20 years of experience in mattress and PU foam manufacturing. Our aim is to produce economically efficient, high-performance, user-friendly, and low-maintenance polyurethane foam and mattress machinery.

We have five production factories, access to resources from ten chemical material factories, and collaborations with over 100 furniture manufacturers in our supply chain. Our team includes five engineers specializing in polyurethane engineering, mechanical engineering, and circuit design, offering personalized one-on-one production technology training. An 8-person after-sales service team commits to responding within one hour. There are sample machines in the workshop available for on-site mechanical operation demonstrations at any time.

To date, we have served 18 factories, assisting them in constructing, upgrading, and renovating their facilities. Providing professional insights for over 60 mattress and PU foam factories on factory planning and layout optimization, improving equipment efficiency, and reducing costs. Resolving mechanical operation issues, quality problems in foaming, and raw material waste issues for over 80 factories.

We meticulously craft every detail of our machines, striving to make them serve workers better, reduce complexity, alleviate the burdens on frontline production workers, increase production efficiency, reduce production costs, and minimize maintenance issues.

Production Process

We believe that it is foolish to sell any fixed type of machinery. Machinery should be upgraded according to different production scenarios to maximize efficiency.

Contact Person: Ruby Lau

Contact Number: +86-18688267265

Email: sales@alforu.cn

WhatsApp: +86-18688267265

Company Address: NO. 18 South Industry Road, Dongguan City, Guangdong Province China